Sheathed element air duct heaters provide a clean and safe method of air heating, which is economical to install and operate, especially if an efficient control system is employed.

The heaters described here are intended for ventilation / air conditioning applications with air leaving temperatures below 60 °C

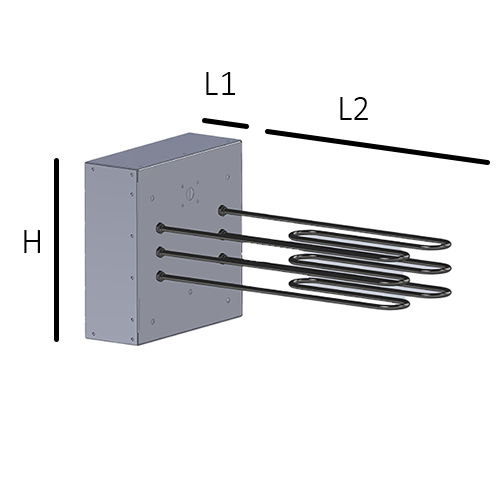

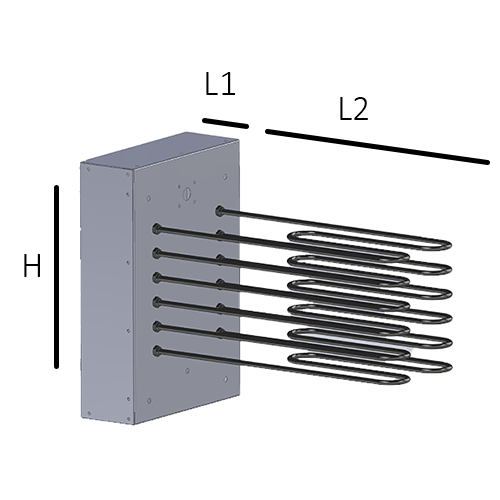

Rectangular duct heater: Flanged duct with "stab-in" type heater section to enable removal of elements without dismantling ductwork.

These heaters can be mounted in a vertical or horizontal position. Please state position when ordering so that the thermal cut-out can be selected to suit the application.

Forced air duct heater comprising sheathed electric resistance elements, mounted in a pre-galvanised steel casing.

Elements consist of a nickel/chromium resistance wire, spirally wound, insulated by compacted magnesium oxide powder and fitted within a incoloy ( AIS1321 titanium stabilised ) tube. The connection bushes of each element are1/4" BSP brass crimped on.

Elements are return bent and mounted in the terminal box with airtight brass fixing glands and insulating washers.

Heaters are designed to have an element suface temperature of 400°C at an air velocity of 2m/s.

Element tails are either fitted with saddle washers for cable connection or linked with copper busbar.

Terminal boxes are made with 1.2mm pre-galvanised steel and generally conform to IP40. 25mm conduit holes and earth stud are provided.

Every heater is fitted with a high temperature safety cut out ( manual reset ). This usually comprises a bi-metallic disc which is non-current sensitive. The switch contacts are normally closed and can withstand 13A at 240V ( this cut out should be connected into the control circuit to break the supply to the heater load ).

PLEASE REFER TO TABLE FOR ELECTRIC HEATER BATTERY RATINGS AND SIZES.

| Reference |

Rating (KW) |

Element Quantity |

H |

W |

L1 |

L2 |

| EHB1/3KW |

5 |

2 |

280 |

270 |

125 |

265 |

| EHB1/4KW |

4 |

2 |

280 |

270 |

125 |

365 |

| EHB1/5KW |

5 |

2 |

280 |

270 |

125 |

465 |

| EHB1/6KW |

6 |

2 |

280 |

270 |

125 |

465 |

| EHB1/7.5KW |

7.5 |

3 |

280 |

270 |

125 |

465 |

| EHB1/9KW |

9 |

3 |

280 |

270 |

125 |

465 |

|

Protection and Fire Safety Requirements

It is recommended to have the air velocity across the elements at 2.5 m3/sec or above to prevent the elements "glowing"

Always install an airflow switch in the system to detect airflow, should the airflow fail then the heater battery needs to immediately shut down.

A Fan run on timer is recommended to allow the fan to "run on" for a minimum of two minutes which allows the heater elements to dissipate the heat.

Please note these items are made to manufacture and once made we cannot accept returns for these items, Lead times for all models 2-3 weeks.