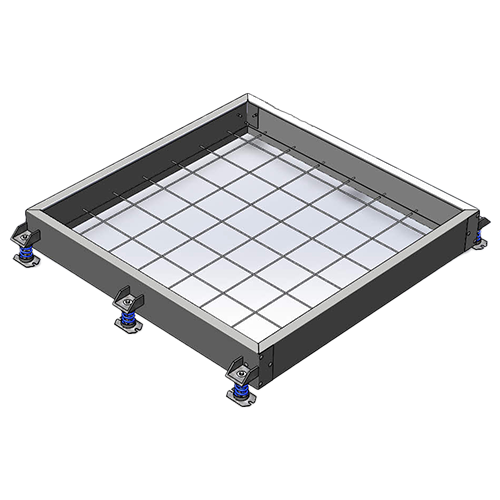

Air Handling Components range of matched inertia bases (anti-vibration mountings sold separately) to vibration isolate rotating and oscillating masses such as: - pumps, generators, chillers, condensing uni, heat pumps, compressor, boilers etc.

the Inertia base frame is manufactured from zinc rich coated steel with strong welded steel brackets to support the open spring anti-vibration mounts (sold separately) matched to suit the load of the mounted mass and concrete filled inertia base.

Steel weld mesh is inserted within the base to add strength to the concrete. Inertia bases are finish painted on the exterior faces also the weld mesh is protective painted.

Inertia Bases are designed on a 1.7 Ratio of base weight to reduce the mass centre of gravity, anti vibration mounts are selected to offer the correct deflection of the combined load of the mass and filled base, anti vibration mounts which are sold separately with the bases are 25mm deflection.

| WIDTH |

LENGTH |

DEPTH |

MOUNTS |

ITEM WEIGHT |

| 600 |

500 |

100 |

4 X AM75 |

60KG |

| 600 |

500 |

150 |

4 X AM75 |

80KG |

| 600 |

500 |

200 |

4 X AM75 |

95KG |

| 600 |

600 |

100 |

4 X AM75 |

65KG |

| 600 |

600 |

150 |

4 X AM75 |

95KG |

| 600 |

600 |

200 |

4 X AM100 |

110KG |

| 750 |

750 |

100 |

4 X AM75 |

80KG |

| 750 |

750 |

150 |

4 X AM100 |

120KG |

| 750 |

750 |

200 |

4 X AM125 |

150KG |

| 1000 |

750 |

100 |

4 X AM100 |

115KG |

| 1000 |

750 |

150 |

4 X AM150 |

160KG |

| 1000 |

750 |

200 |

4 XAM200 |

210KG |

| 1000 |

1000 |

100 |

4 X AM125 |

140KG |

| 1000 |

1000 |

150 |

4 X AM200 |

215KG |

| 1000 |

1000 |

200 |

4 X AM250 |

275KG |

| 1200 |

1000 |

100 |

6 X AM100 |

185KG |

| 1200 |

1000 |

150 |

6 X AM150 |

275KG |

| 1200 |

1000 |

200 |

6 X AM200 |

380KG |

| 1200 |

1000 |

250 |

6 X AM250 |

455KG |

| 1200 |

1200 |

100 |

6 X AM125 |

220KG |

| 1200 |

1200 |

150 |

6 X AM200 |

325KG |

| 1200 |

1200 |

200 |

6 X AM250 |

435KG |

| 1200 |

1200 |

250 |

6 X AM350 |

540KG |

| 1500 |

600 |

100 |

6 X AM75 |

135KG |

| 1500 |

600 |

150 |

6 X AM125 |

200KG |

| 1500 |

600 |

200 |

6 X AM150 |

275KG |

| 1500 |

600 |

250 |

6 A SM200 |

340KG |

| 1500 |

750 |

100 |

6 X AM100 |

170KG |

| 1500 |

750 |

150 |

6 X AM150 |

250KG |

| 1500 |

750 |

200 |

6 X AM200 |

340KG |

| 1500 |

750 |

250 |

6 X AM250 |

430KG |

| 1500 |

1000 |

100 |

6 X AM125 |

225KG |

| 1500 |

1000 |

150 |

6 X AM200 |

340KG |

| 1500 |

1000 |

200 |

6 X AM250 |

455KG |

| 1500 |

1000 |

250 |

6 X AM300 |

560KG |

| 1500 |

1250 |

100 |

6 X AM150 |

280KG |

| 1500 |

1250 |

150 |

6 X AM250 |

420KG |

| 1500 |

1250 |

200 |

6 X AM350 |

560KG |

| 1500 |

1250 |

250 |

6 X AM450 |

760KG |

| 1500 |

1500 |

100 |

8 X AM150 |

330KG |

| 1500 |

1500 |

150 |

8 X AM200 |

500KG |

| 1500 |

1500 |

200 |

8 X AM350 |

670KG |

| 1500 |

1500 |

250 |

8 X AM350 |

845KG |

| 1500 |

1500 |

300 |

8 X AM450 |

1000KG |

| 1750 |

750 |

100 |

8 X AM100 |

200KG |

| 1750 |

750 |

150 |

8 X AM125 |

300KG |

| 1750 |

750 |

200 |

8 X AM200 |

400KG |

| 1750 |

750 |

250 |

8 X AM200 |

500KG |

| 1750 |

750 |

300 |

8 X AM250 |

600KG |

| 1750 |

1000 |

100 |

8 X AM125 |

265KG |

| 1750 |

1000 |

150 |

8 X AM200 |

400KG |

| 1750 |

1000 |

200 |

8 X AM250 |

530KG |

| 1750 |

1000 |

250 |

8 X AM350 |

660KG |

| 1750 |

1000 |

300 |

8 X AM350 |

790KG |

| 1750 |

1250 |

100 |

8 X AM150 |

330KG |

| 1750 |

1250 |

150 |

8 X AM200 |

490KG |

| 1750 |

1250 |

200 |

8 X AM350 |

660KG |

| 1750 |

1250 |

250 |

8 X AM350 |

820KG |

| 1750 |

1250 |

300 |

8 X AM450 |

985KG |

| 1750 |

1500 |

100 |

8 X AM150 |

390KG |

| 1750 |

1500 |

150 |

8 X AM250 |

590KG |

| 1750 |

1500 |

200 |

8 X AM350 |

790KG |

| 1750 |

1500 |

250 |

8 X AM450 |

985KG |

| 1750 |

1500 |

300 |

8 X AM550 |

1182KG |

| 1750 |

1750 |

100 |

12 X AM150 |

460KG |

| 1750 |

1750 |

150 |

12 X AM200 |

685KG |

| 1750 |

1750 |

200 |

12 X AM250 |

920KG |

| 1750 |

1750 |

250 |

12 X AM350 |

1150KG |

| 1750 |

1750 |

300 |

12 X AM350 |

1375KG |

| 2000 |

750 |

100 |

12 X AM75 |

230KG |

| 2000 |

750 |

150 |

12 X AM100 |

340KG |

| 2000 |

750 |

200 |

12 X AM125 |

450KG |

| 2000 |

750 |

250 |

12 X AM150 |

565KG |

| 2000 |

750 |

300 |

12 X AM200 |

740KG |

| 2000 |

1000 |

100 |

12 X AM100 |

300KG |

| 2000 |

1000 |

150 |

12 X AM125 |

456KG |

| 2000 |

1000 |

200 |

12 X AM200 |

605KG |

| 2000 |

1000 |

250 |

12 X AM250 |

750KG |

| 2000 |

1000 |

300 |

12 X AM250 |

905KG |

| 2000 |

1250 |

100 |

12 X AM100 |

375KG |

| 2000 |

1250 |

150 |

12 X AM150 |

565KG |

| 2000 |

1250 |

200 |

12 X AM200 |

750KG |

| 2000 |

1250 |

250 |

12 X AM250 |

940KG |

| 2000 |

1250 |

300 |

12 X AM250 |

1125KG |

| 2000 |

1500 |

100 |

12 X AM125 |

450KG |

| 2000 |

1500 |

150 |

12 X AM200 |

676KG |

| 2000 |

1500 |

200 |

12 X AM250 |

900KG |

| 2000 |

1500 |

250 |

12 X AM350 |

1125KG |

| 2000 |

1500 |

300 |

12 X AM350 |

1350KG |

| 2000 |

1750 |

100 |

12 X AM150 |

525KG |

| 2000 |

1750 |

150 |

12 X AM200 |

785KG |

| 2000 |

1750 |

200 |

12 X AM350 |

1050KG |

| 2000 |

1750 |

250 |

12 X AM350 |

1310KG |

| 2000 |

1750 |

300 |

12 X AM450 |

1570KG |

| 2000 |

2000 |

100 |

12 X AM200 |

610KG |

| 2000 |

2000 |

150 |

12 X AM250 |

900KG |

| 2000 |

2000 |

200 |

12 X AM350 |

1200KG |

| 2000 |

2000 |

250 |

12 X AM450 |

1495KG |

| 2000 |

2000 |

300 |

12 X AM550 |

1800KG |

|

Work to be carried out on site

STAGE ONE

The inertia base frame to be laid in position on a sheet of plastic or roof felt.

STAGE TWO

Fill the frame with concrete. Tamp down the level and smooth the surface

STAGE THREE

Position the item to be isolated onto the concrete and bolt down securely.

Fit the anti-vibration mountings to the pre-drilled isolator brackets on the inertia base.

STAGE FOUR

Using the anti-vibration mounting adjusting screw, jack up the inertia base to give the25mm ground clearance. Make sure the inertia base is level.

If pipework, electrical conduit/trunking, ductwork etc is fixed to items on the inertia base, make sure that they are adequately supported and flexibly isolated from rigidly positioned items external to the inertia base.